Contents

Assembly

Calibration & Maintenance

Kyowa America understands the importance of maintenance. Our machines are regularly maintained

and calibrated to minimize machine downtime, variability and quality degradation. Our long history of

producing quality parts has taught us that these preventative maintenance steps reduce the number of

surprises on the factory floor.

Vibration Welding

Our vibration welders (on the left) are capable of welding large parts together using

vibrational friction to melt the parts together at their contact points.Your design can be simplified

with this process - no fasteners, no complicated molding necessary. Our diverse manufacturing

capabilities expand your design possibilities.

Hardware Installation

Kyowa America has the ability to develop your product from concept to completion. After molding, the part must sometimes need to be assembled with various hardware, pads, or labels. Our operators are quick, thorough and well-trained. They are backed by experienced inspectors to provide an added level of quality assurance that can ensure that the part arrives complete and to customer specifications.

Inspection

Variations are an undesired but inevitable truth in all manufacturing processes.

Our trained inspectors are capable of quickly inspecting parts with the utmost care for customer

specifications to find these variations. Each part is checked for contamination, blemishes or other

molding errors that don't meet customer needs.

Defects are recorded for variability analysis and ISO Key Performance Indicator (KPI) data.

This data is then used to find ways to improve our processes.

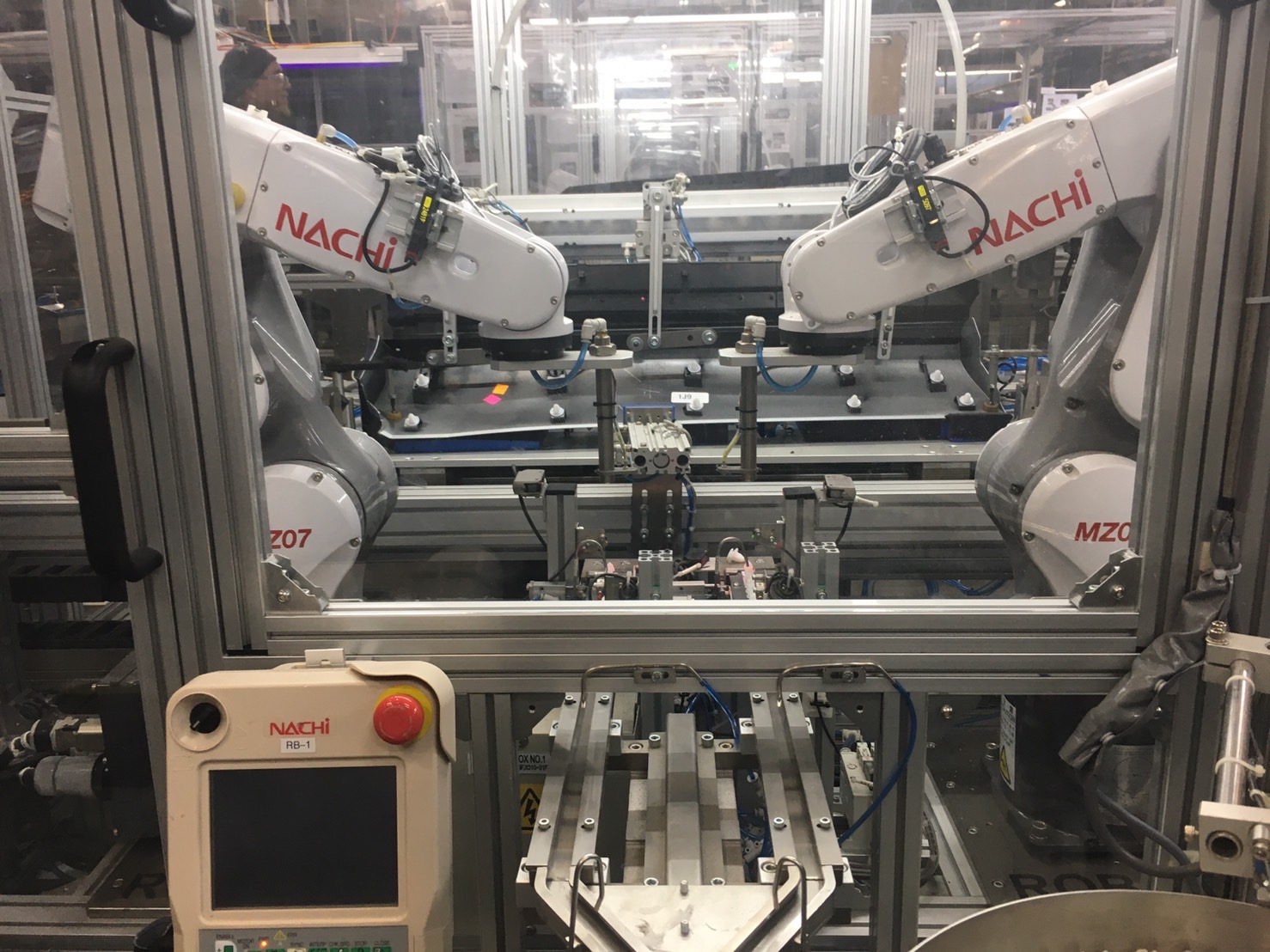

Automated processes

Maximum efficiency is our goal. If there is a process that can save time and money,

we will thoroughly consider it. We frequently use automated processes in situations where quality

is key for repeatable results.